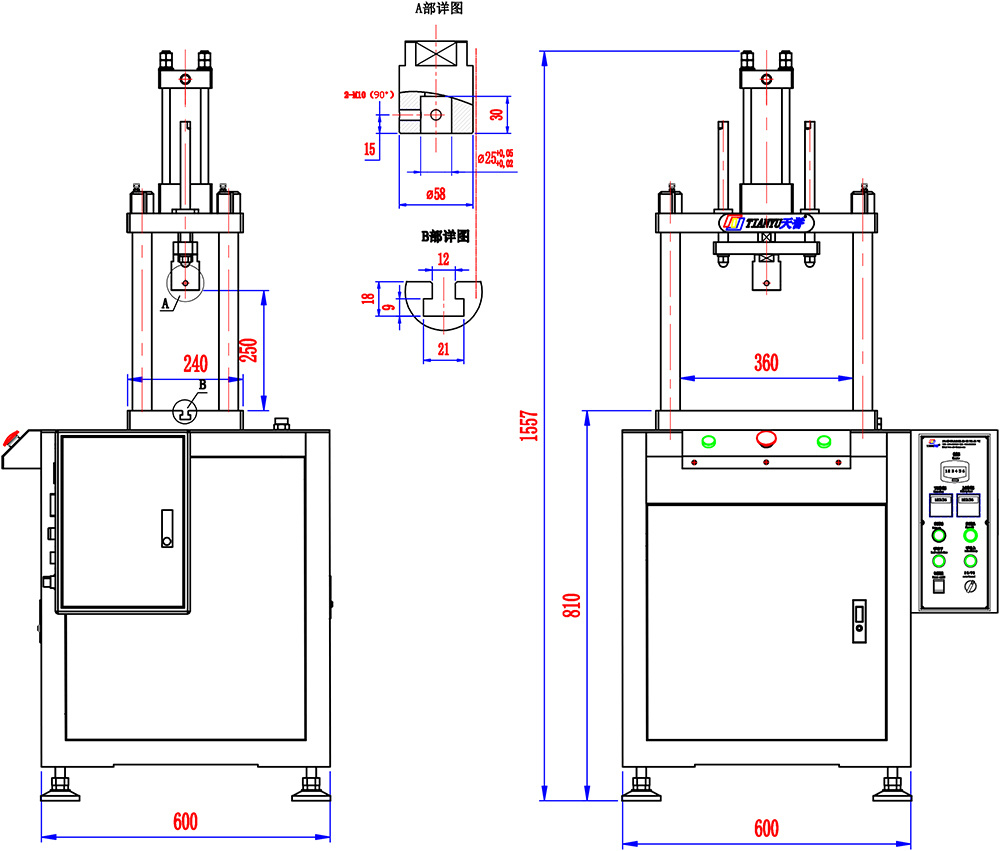

TY303 four-column hydraulic press

Classify:

TY701 series integrated head quantitative vacuum filling machine is a new type of integrated head quantitative vacuum filling machine independently developed by our company in combination with the technological characteristics and pain points of product filling in the industry. It has the characteristics of high efficiency, fast pumping speed and no residual liquid. It is mainly used for liquid perfusion of automobile rubber bushing and rubber suspension.

Keywords: Filling equipment series

- Product Description

- Technical Parameter

-

- Commodity name: TY303 four-column hydraulic press

- Commodity ID: F003

The fuselage adopts a four-column structure. Compared with the C-type single-column structure, it has higher vertical accuracy and strong overload resistance. It is mainly used for pressing various shafts, shallow stretching of metal products, pressing for molding, and bending and embossing of parts. , Sleeve shape, is a general-purpose small press-fitting equipment for manufacturers of internal combustion engines, textile machinery, shafts, bearings, washing machines, auto parts, motors, and electrical appliances.

Application field

◎ Automobile industry: engine component press assembly (cylinder head, cylinder liner, oil seal, etc.), steering gear assembly press assembly (gear, pin, etc.), transmission shaft assembly press assembly, gear box assembly press assembly, brake disc assembly press assembly, etc.

◎ Motor industry: press-fitting of micro-motor components (spindle, housing, etc.), press-fitting of motor components (bearings, spindles, etc.);

◎ Electronics industry: circuit board components (plug-ins, etc.), electronic parts and components;

◎ Home appliance industry: press fitting of home appliance parts, riveting of home appliance parts, etc.

◎ Machinery industry: press-fitting of mechanical parts, automatic assembly line, life test of wearing parts, etc.

◎ Other industries: other industries that require precise control of press-fitting displacement and press-fitting force;

product description

The fuselage adopts a four-column structure. Compared with the C-type single-column structure, it has higher vertical accuracy and strong overload resistance. It is mainly used for pressing various shafts, shallow stretching of metal products, pressing for molding, and bending and embossing of parts. , Sleeve shape, is a general-purpose small press-fitting equipment for manufacturers of internal combustion engines, textile machinery, shafts, bearings, washing machines, auto parts, motors, and electrical appliances.

Features

1. This series of hydraulic press uses 1-14MPA as the power source, and is connected to a three-phase AC380V 50HZ or three-phase AC220 60HZ AC power supply. The total power consumption does not exceed 2.2KW;

2. This series of equipment uses liquid as a medium to transfer energy, is flexible in control, easy to realize automation, and operates at a uniform speed. Compared with pneumatic equipment, the speed and pressure are adjustable and controllable, with a large output adjustment range, strong independence and better performance. Stable, which can greatly improve the quality of press-fitting products;

3. There are two control modes: manual and semi-automatic. Manually, the press-fit upper die can be stopped within any range of travel, equipped with an emergency lift button, and an infrared hand guard can also be installed;

4. The press-fitting stroke of this series of presses is generally controlled by a pressure switch, a position sensor, or the customer's own mold;

5. The lifting height of the press-fitting spindle is controlled by the position sensor switch and can be stopped within any range of travel;

6. The descending speed of the spindle is 78MM/S for 30KN, 68MM/S for 50KN, 68MM/S for 100KN;

7. Customers can adjust the pressure, stroke, holding time, and closing height by themselves, which is convenient for operation;

8. The hydraulic system meter has a built-in bottom of the oil tank, with a clean and stable appearance;

9. It has an automatic counting function, and can also be equipped with a force measurement display, which can be customized according to customer requirements;

-

Technical parameters

Model

TY303-30

TY303-50

TY303-80

TY303-100

Cylinder pressure

3-30KN

5-50KN

5-80KN

30-100KN

Liquid pressure

l0Mpa

16Mpa

16Mpa

13Mpa

Cylinder stroke

150MM

150MM

150MM

150MM

Descait speed

60MM/S

60MM/S

58MM/S

68MM/S

Rise speed

90MM/S

90MM/S

77MM/S

88MM/S

Motor porer

2.2KW

2. 2KW

3. 7KW

3.7KW

Machine weight

220KG

225KG

250KG

270KG

Power siqjply

AC380V 50HZ

Recommended Products

Online message

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!